Electronics

22VISION Ideal state

We aim to become a top global supplier of high-performance wiring and high-performance components, mainly for mobile devices and mobile electronics

Overview of Business

The dramatic increase in volumes of data being transmitted to and from mobile devices has accelerated development to handle new functions and standards. There is also a growing need for car electronics products and aviation equipment as the world turns to EVs and self-driving cars. The Sumitomo Electric Group is an indispensable part of these markets' growth. We develop a wide range of materials, wires and parts to be used in various electronic devices.

Flexible printed circuits (FPCs) are one of the main products of the group. Their versatility in forming high-density circuits in a small area makes them a wiring material adaptable to all kinds of increasingly complex equipment. We have electron beam irradiation technology used to produce electric wire products and heat-shrinkable tube, and fluorine resin processing technology such as Poreflon™ Module. We draw on strengths such as our proprietary material development, design and processing technologies and high-speed data transmission technology to make our supply chain more competitive on a global stage and serve as a global supplier of high-performance wiring and high-functionality materials.

VISION 2022 Mid-term Management Plan: Segment Strategy

FY2020 Results

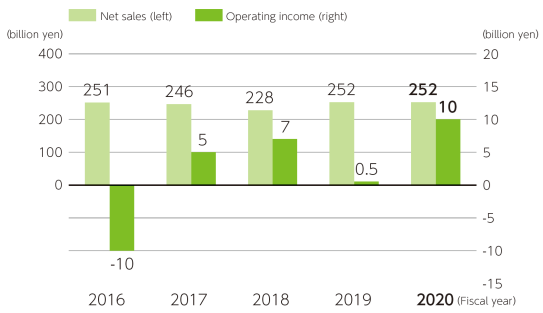

Sales of flexible printed circuits (FPCs) for mobile devices decreased, but demand for electronic wire products such as lead wires for battery terminals (tab leads) increased, and Techno Associe Co. Ltd., which became a subsidiary in the second quarter of the previous year, contributed to the increase. Net sales were almost unchanged from the previous fiscal year at 252,618 million yen (up 448 million yen, or 0.2% year-on-year). As a result of profit recovery efforts such as increased sales of electronic wire products and cost improvement and withdrawal from non-profitable products in FPCs for mobile devices, operating income increased by 9,511 million yen to 10,047 million yen.

Priority initiatives for FY2021

●Concerning FPCs、while continuing our efforts to improve profitability by optimizing our global production system and implementing productivity improvements, we will also expand sales for automotive applications and accelerate the development of high-definition and high-frequency compatible new products.

●We will strive to expand businesses that capture diverse customer needs for lead wires for battery terminals of electric vehicles (tab lead), electric wires for electric parking brakes, heat-shrinkable tubes, and water treatment products, leveraging our proprietary technologies such as electron beam irradiation and fluoroplastic processing.

●We will work to expand business synergies with Techno Associe Co., Ltd., which joined the Group last fiscal year.

Examples of our initiatives to solve social issues

Poreflon™

Today, the issue of water pollution has become a global issue. In particular, in emerging countries where economic development is remarkable, industrialization and the concentration of population in cities is advancing, and river pollution caused by factory and household wastewater is affecting human health and ecosystems.

The Poreflon™* filtration membrane modules for industrial wastewater and sewage treatment, which the Group has been manufacturing since 2003, have superior chemical resistance, high strength, high water permeability, and heat resistance, and have been delivered to a large number of customers in the industrial wastewater segment in Japan, Asia, and North America. Membrane wastewater treatment system using the Poreflon™ module as a key component in a system consisting of a membrane submersion tank, pump, aeration blower, control panel, etc., exhibit stable performance regardless of changes in wastewater volume, concentration, weather conditions, etc., and offer substantial improvements in energy costs and required installation space. We will continue to take advantage of the strengths of Poreflon™ to contribute to the conservation of the water environment for people around the world.

*Poreflon™ : A porous material made of 100% PTFE (polytetrafluoroethylene resin) manufactured by Sumitomo Electric Industries, Ltd.