The Cross Linked Fluorine Resin FEX™

What is FEX™?

FEX™ : Crosslinked Perfluorinated Polyethylene

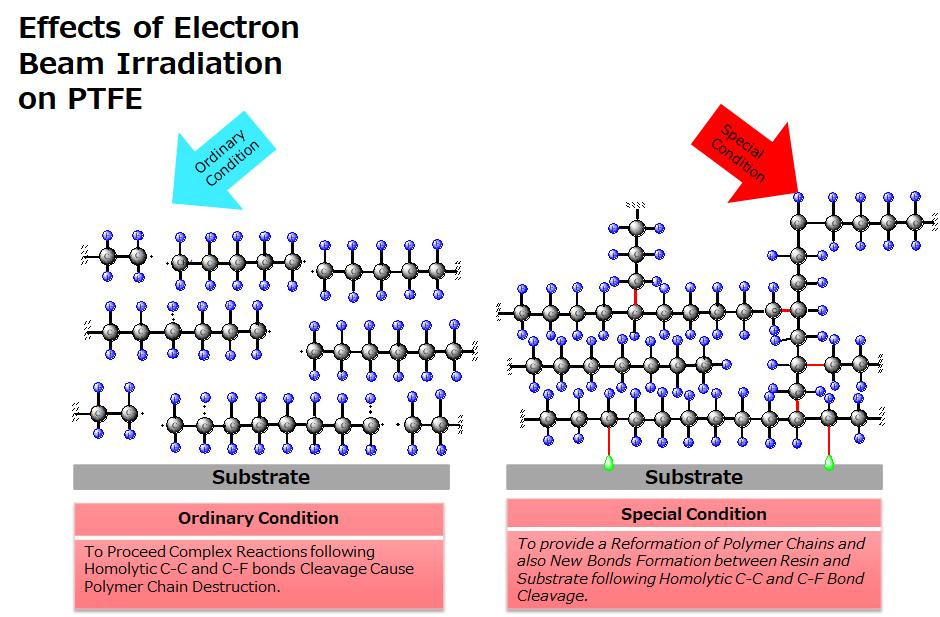

FEX™ is a functional fluororesin coating technology which takes advantage of the low coefficient of friction of conventional flurororesins while showing an exceptional improvement in wear resistance. There is a FEX™ tape which has the low coefficient of friction and high wear resistance.

It is based on our state of the art electron beam cross- linking technology combined with our original fluororesin coating techniques.

Advantages

-

High Abrasion Resistance without Fillers

-

High Adherence to Substrates

Principle

Contact Us

The inquiries will be redirected to Functional Materials Sales & Marketing Department.

Inquiry FormApplications of The FEX™ Coating

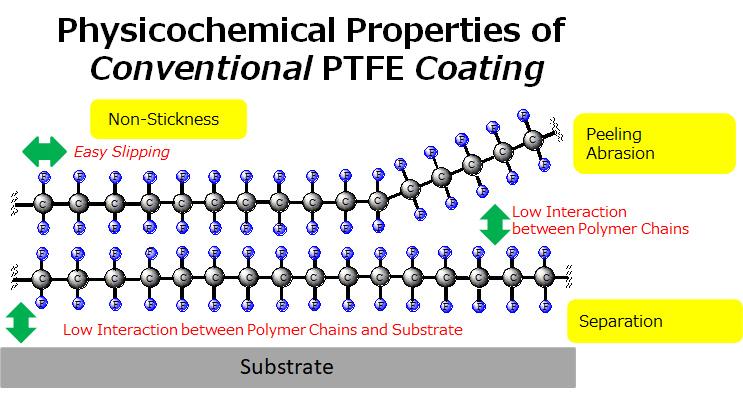

| Conventional PTFE Coating |

FEX™PTFE Coating |

|

|---|---|---|

| Abrasion Resistance | 1 | 1,120 |

| Adhesion to Substrate | Difficult | Adhesible |

| Dynamic Friction Coefficient | Minimum(0.06~0.1) | same |

| Thermo Stability | 260℃ | same |

| Chemical Stability | Stable | same |

| Flame Retardancy (Limiting Oxygen Index) |

Over 95% | same |

| Weatherability | Excellent | same |

| Permittivity(10³~10⁶Hz) D150 |

Minimum(2.1) | same |

| Dissipation Factor(10⁶Hz) D150 |

Minimum(2×10-³) | same |

| Pencil Hardness | HB | same |

Applications of The FEX™ Coating

Coating prior to Molding

FEX™ Coated metal plates are molded into optional shapes by press working.

Also, FEX™ Coated metal plates could be supplied.

Coating on arbitrary shapes

FEX™ Coating is applicable to various shaped substrate.

Contact Us

The inquiries will be redirected to Functional Materials Sales & Marketing Department.

Inquiry Form