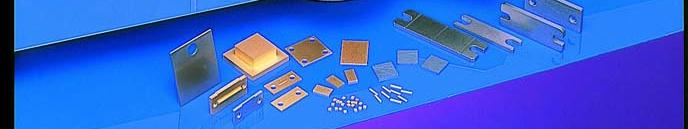

Cu-W (Copper-Tungsten)

Heatspreaders for Opto electronics, Wireless communication, LED substrates

Cu-W is a combination of Tungsten (W) which has low thermal expansion, and Copper (Cu) which has high thermal conductivity. The thermal expansion can be adjusted to surrounding materials such as Alumina and Kovar. Also, with its good machinability, it’s possible to manufacture the parts with small-complex shaped. We offer 6 types of Cu-W (W-6, W-10, W-15, W-20, W-10N, W-10T) according to customer needs.

| Material | Trade Name | Composition | Features | Coefficient of Average Linear Thermal Expansion R.T.~800℃ [ppm/K] |

Thermal conductivity R.T.[W/(m・K)] |

|---|---|---|---|---|---|

| Cu-W | W-6 | 94W-6Cu | This Cu-W with a low coefficient of thermal expansion has the close coefficient to GaAs and GaN. And, it prevents mismatches of the thermal expansion. | 6.4 | 141 |

| W-10 | 89W-11Cu | The coefficient of thermal expansion matches alumina. So, it is widely used in ceramic packages using alumina. | 7.9 | 174 | |

| W-15 | 85W-15Cu | The same thermal expansion coefficient as that of beryllia ceramics, widely used for ceramics package using beryllia. It is also widely used for packages using both alumina and kovar because its thermal expansion coefficient is an intermediate value between those of alumina and kovar. | 8.6 | 184 | |

| W-20 | 80W-20Cu | It matches the coefficient of thermal expansion of Kovar and is widely used in metal packages using Kovar. | 9.8 | 200 | |

| W-10N | 89W-11Cu | The coefficient of thermal expansion matches alumina. It is widely used in ceramic packages using alumina.W-10N can provide Cu-W (near-net Cu-W) without periphery process by manufacturing a dedicated mold. | 7.9 | 200 | |

| W-10T | 89W-11Cu | Although it has the same thermal expansion coefficient as that of W - 10, the thermal conductivity is improved by a special manufacturing method; moreover, it is widely used for sub-mount applications for high power lasers because it can keep warp small. | 7.9 | 205 |