2012年7月号 No.181

特集「切削工具 ~高機能化・省資源技術動向と新製品~」

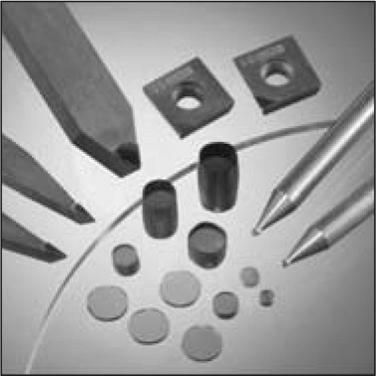

鉄族金属、非鉄金属の切削に用いられる工具のうち、約90%は超硬合金もしくはコーティド超硬合金が用いられている。超硬合金(WC-Co)はタングステンカーバイド(WC)を硬質相とし、コバルト(Co)をバインダとした複合材料であり、1923年にドイツで発明され、1927年に「ウィディア」と名付けられて独クルップ社から発売された。当社も1928年に線引きダイスの試作に成功、1931年には切削用バイトとして商品化し、2011年に「イゲタロイ®」誕生80周年を迎えることができた。鋼切削用工具として古くは1900年代初頭に高速度鋼(ハイス)工具が登場したが、超硬合金はハイスよりも高速加工が可能であり、更に1970年代後半にはアルミナやTi化合物を被覆したコーティド超硬が開発され、より高速で切削が可能となり、80年間の歴史を経ても今なお切削工具材料の中で主流の座を占めている。その他、ジェットエンジン材料の開発から生まれたサーメット(TiCN-Ni)工具は鋼材料に対する低い親和性 を活かして仕上げ切削に用いられ、アルミナ酸化物(Al2O3)、窒化珪素(Si3N4)などを主体にしたセラミック工具もその耐

205 KB

205 KB

Various efforts have been undertaken to lessen the environmental burden. In the automotive industry, for example, cast iron parts and other components have been made lighter mainly to reduce exhaust gas emissions and improve fuel efficiency. For the weight reduction, these components have increasingly thin walls and complex designs, and thus, high-strength, difficult-to-cut materials are used. Meanwhile, there is also a strong demand for high-speed and high-efficiency machining to reduce lead

0.6 MB

0.6 MB

“SUMIBORON” PCBN (polycrystalline cubic boron nitride) tools are widely used in the cutting of hard-to-cut ferrous materials, such as hardened steel, cast iron and powder metal, and contribute to productivity growth and cost reduction for metalworking. In the recent growing automotive industry, the machining of cast iron and powder metal parts has been increasingly required. Conversely, however, the machinability of these parts has been degraded because of their high functionality.

0.5 MB

0.5 MB

The authors have succeeded in the production of single-phase (binderless) nano-polycrystalline diamond (NPD) by the direct conversion sintering of graphite at ultra-high pressure and temperature. NPD, consisting of diamond grains of several tens of nanometers, features fine texture, extreme hardness, and high strength without showing cleavage features and anisotropy of mechanical properties. These salient characteristics indicate that NPD has outstanding potential as industrial material

0.5 MB

0.5 MB

General-purpose face milling cutters are widely used in metal machining. These tools are required to reduce machining cost and offer a wide range of applications. Furthermore, they need to ensure excellent surface finishing for highly functional parts. To address these challenges, Sumitomo Electric Hardmetal Corporation has developed a new milling cutter “SEC-Dual Mill DGC” series for general-purpose face milling. This series employs negative inserts which can be used on both sides to enable

324 KB

324 KB

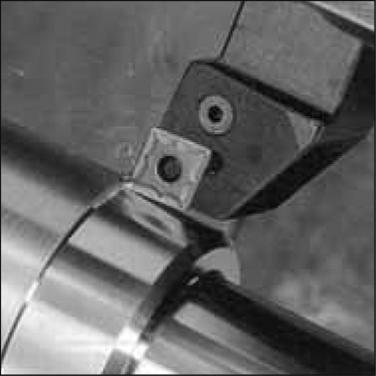

Grooving is widely applied in machining automotive parts and other industrial components. Compared with general cutting, however, grooving is subject to problems such as difficulty in chip evacuation, which can result in defective groove surfaces, and tool vibration due to the high load operation with the entire cutting edge width. To improve processing efficiency and accuracy while minimizing the cost of grooving tools, Sumitomo Electric Hardmetal Corporation has developed new grooving tools

0.6 MB

0.6 MB

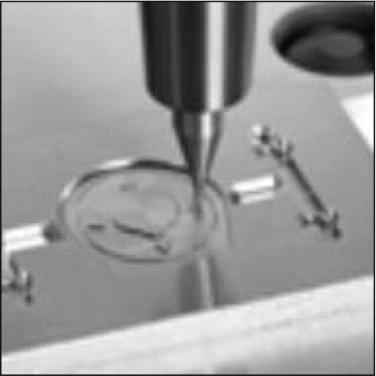

In recent years, mold manufacturers have been prompted to provide low-cost, high-precision products and shorten the delivery time in response to the miniaturization of products and price competition in the global market. Due to this trend, mold manufacturers desire to shift their manufacturing method of hardened steel from electric discharge processing with copper electrodes to direct cutting. Sumitomo Electric Hardmetal Corporation has newly released the cubic boron nitride (CBN) BNBR endmills

0.6 MB

0.6 MB

Tungsten is a base material of cemented carbide tools widely used in automotive, electronic equipment, construction and other industrial fields. Since tungsten is a rare metal produced in a limited number of countries, it is subject to supply risks. We have addressed this problem by recycling and reducing the use of tungsten. While the hydrometallurgy process that we developed for recycling can recover tungsten oxide with nearly the same quality as ore refining from any kind of scrapped cemented

1 MB

1 MB

Gallium nitride (GaN) and other nitride compound semiconductors show high potential as optical and electronic devices. Sumitomo Electric Industries, Ltd. has been researching this potential, and in the early 2000s succeeded in developing the world’s first 2-inch GaN single crystal substrates with high quality and low dislocation density, which were essential features for violet lasers, by using vapor phase growth technique. Moreover, we have worked on the development of optical and electronic

0.6 MB

0.6 MB

Radiation chemistry is commonly used in manufacturing industrial products such as heat resistant electrical wires used in the electrical appliances, rubber material used in automotive tires, heat shrinkable tubes and films, foamed material, and battery separators. In radiation chemistry, electron beams are more widely used than gamma rays because of the good handling and operating characteristics, particularly for safety reasons. NHV Corporation has been concentrating its efforts on the

0.5 MB

0.5 MB

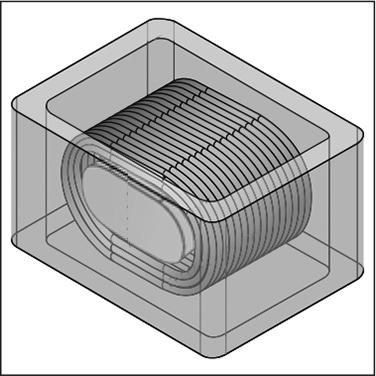

Sumitomo Electric Industries, Ltd. has developed magnetic powder core materials for power inductors used in eco-friendly vehicles. Pure iron based powder cores with an operating frequency range from 10kHz to 30kHz have been used for boost converter reactors in hybrid-electric vehicles (HEVs), while low-loss Fe-Si-Al alloy powder cores with an operation range of several hundred kHz have shown the potential to replace ferrite cores for buck converter choke coils. Our low-loss alloy powder cores

0.7 MB

0.7 MB

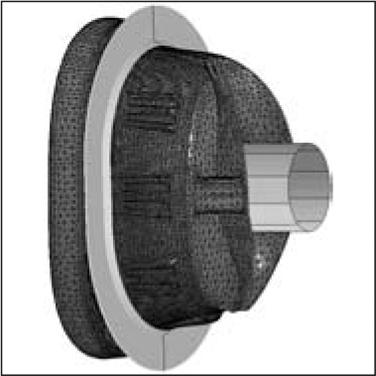

Sumitomo Wiring Systems, Ltd. designs and develops rubber grommets used for the protection and sealing of automotive wiring harnesses. These grommets are required to have good sealing properties, reduce the insertion force, and increase the removing force. To evaluate the insertion and removing forces, we use computer-aided engineering (CAE), in which the calculation results conform to the experimental results by reflecting the frictional force and material properties. We can also evaluate the

0.6 MB

0.6 MB

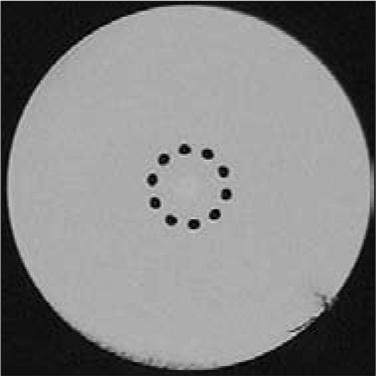

As the optical access network expands, there is an increasing demand for optical fiber cables that improve Fiber-to-the-Home (FTTH) network installation and maintenance efficiency. To meet this demand, bend insensitive fibers (BIFs) have been developed. Among BIFs, hole-assisted fiber (HAF) shows excellent bending loss characteristics by the strong light confinement effect of air-holes surrounding the center core. Recently, single-mode HAF (SM-HAF) has been demonstrated to show low bending loss

307 KB

307 KB

As of September 2011, the number of FTTH subscribers in Japan has reached 21 million and is forecast to increase at a consistent pace. To construct FTTH networks more economically, a distribution system using underground conduits has been proposed. In this system, distribution cables are installed in underground conduits and drop cables are routed to each subscriber’s home upon request for FTTH service at the midpoint of distribution cable. Here we have developed 40-fiber and 100-fiber cables

0.4 MB

0.4 MB

As the amount of Internet traffic increases every year, expectation is growing for 10 Gigabit Ethernet passive optical network (10G-EPON) technology that enables high-speed data transmission. For a smooth replacement of the currently-used GE-PON, 10G-EPON needs to support a maximum channel insertion loss of 29 dB and to coexist with GE-PON in the same optical network. In addition, reduction in capital and operating expenditures is required. To meet these demands, optical transceivers can be a

0.4 MB

0.4 MB

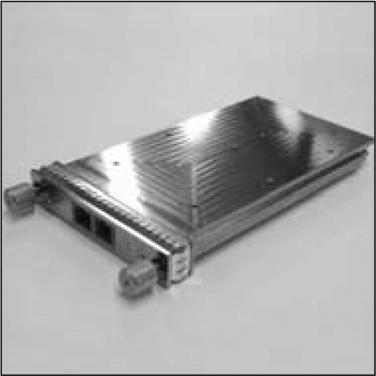

The authors have successfully developed optical transceiver modules operating at 43 Gbit/s and 112 Gbit/s. They are compliant with the ITU-T (International Telecommunication Union Telecommunication Standardization Sector) standard and the CFP MSA (Centum gigabit Form factor Pluggable Multi-Source Agreement) specification and they showed excellent performance with lower power consumption by leveraging in-house optical devices, ICs, and optical subassemblies. This paper describes the outline of

0.4 MB

0.4 MB

Existing license plate detection methods have a good success rate in detecting one or a few fixed formats, however, they may fail in some cases such as motorcycles in Japan and foreign vehicles traveling across national borders. The authors have developed a novel method to detect different types of license plates. This method employs Histogram of Oriented Gradients (HOG)-based bag-of-features, which enables the detector to identify characters’ common curves on different types of plates.

325 KB

325 KB

In Japan, automatic license plate recognition systems have been used for more than ten years for measuring the time required for a vehicle to travel between different points and for applications which need detailed plate information. Due to their efficacy, these systems are now being utilized throughout the country. To better respond to the requirements in these applications, we have developed an automatic license plate recognition device that features a high recognition rate, low failure rate,

0.4 MB

0.4 MB

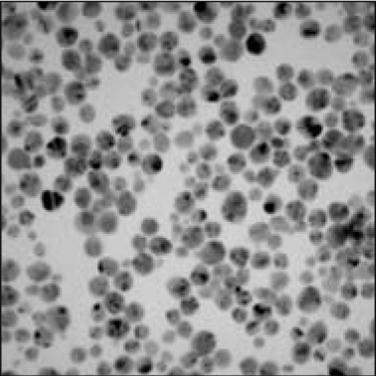

Flexible printed circuit (FPC) boards need to have fine pitch patterns for lighter, thinner and smaller electronic equipment, and connection technology for metal layers (other than copper) is required for FPC diversification. Conductive paste via connection technology offers advantages for manufacturing fine pitch FPC boards and can be applied to non-copper metal layers. The authors have developed highly reliable via connecting technology using conductive paste containing silver nano particles.

0.4 MB

0.4 MB

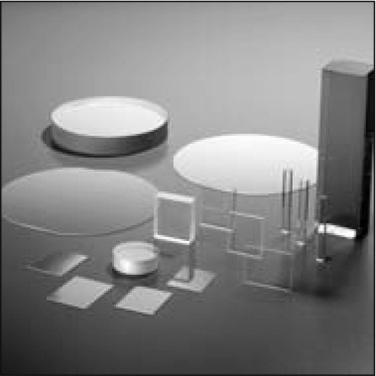

This paper proposes use of polycrystalline spinel for the temperature compensation of radio frequency (RF) surface acoustic wave (SAW) devices. It shows that spinel can be bonded with LiTaO3 (LT) and LiNbO3 (LN) wafers using the adhesive and direct bonding techniques. Series of RF SAW resonators were fabricated on the LT (LN)/spinel structure, and their performance, including the temperature coefficient of frequency (TCF), was measured. For comparison, SAW resonators employing Si and sapphire

290 KB

290 KB

Thunderbolt is an innovative high-speed input/output (I/O) technology developed by Intel Corporation. It enables 10Gbp/s transmission between a computer and peripheral devices. Based on Intel's technical specifications, Sumitomo Electric developed a Thunderbolt electrical cable by combining its advanced cable technology with the high-speed transmission technology. The Thunderbolt cable utilizes differential data transmission technology using pairs of coaxial cables that boast excellent signal in

2.6 MB

2.6 MB

With a record-low birthrate and rapidly-growing elderly population, Japan faces a severe demographic challenge compounded by a chronic lack of nursing-care staff. High-function welfare apparatuses are attracting attention as effective tools to reduce the burden of caregivers and to compensate for the lack of nursing-care staff. Related research and development have been widely conducted, and as a result, the necessity of flexible tactile sensors as human-machine interfaces is increasing.

0.6 MB

0.6 MB

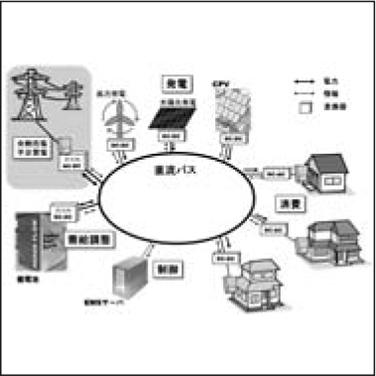

A DC micro grid system has been proposed as a power network that enables the introduction of a large amount of solar energy using distributed photovoltaic generation units. To test the feasibility of the system, we have developed a demonstration facility consisting of silicon photovoltaic (Si-PV) units, copper indium gallium (di)selenide photovoltaic (CIGS-PV) units, concentrating photovoltaic (CPV) units, an aerogenerator, and redox flow battery. The redox flow battery,

0.5 MB

0.5 MB

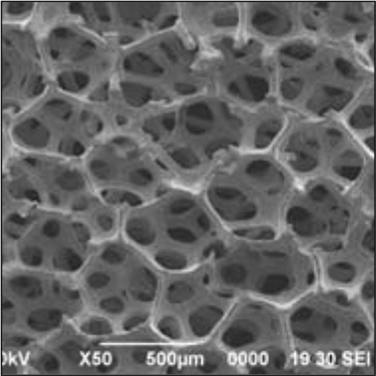

The authors have developed a novel porous metal with high corrosion resistance. Porous materials are used in fuel cells as the current collector and gas diffusion layer of the electrode. Typical porous materials include carbon sheet, molded carbon and porous metals such as stainless used steel (SUS) and nickel chrome (Ni-Cr) alloys. Among these materials, porous metals are preferable because of their high gas diffusion performance. Because of the highly oxidizing atmosphere in fuel cells,

329 KB

329 KB

High-carbon steel wires, such as piano, hard-drawn, or oil-tempered wire, are used for automotive and electronic parts. Despite their outstanding advantages in strength, ductility, and fatigue resistance, these wires are susceptible to fracture due to the brittle as-quenched martensite structure formed by welding. To overcome this problem, we have developed a high-strength steel wire that consists of a bainitic matrix phase to enhance weldability, by adding carbide former elements to low-carbon

0.4 MB

0.4 MB