Registration of public notification

If you register your e-mail address, we will notify you when the latest issue is published. If you wish, please register from the registration form. To delete your registration, please visit here.

October 2022 No.95

We have developed a new analysis technology to accurately calculate the bending shape and bending load of multi-core composite cables installed in the undercarriage of automobiles. The multi-core composite cables are made by bundling multiple electric wires (core wires) and integrating them. They connect the electric parking brake, wheel speed sensor, etc. arranged in the wheel to the vehicle body-side unit, and are responsible for power supply and signal transmission. Demand for the cables is increasing with the electrification of automobiles and technical development of advanced driver-assistance systems (ADAS). The appealing point of the cable is the bending resistance, which prevents the conductor from breaking even when it is repeatedly bent due to the vertical movement of the wheel during traveling. In the past, the cable design was performed after determining the actual vehicle layout shape using CAD, but the calculation accuracy of the bending load was low, and the cable design had to be adjusted during prototyping and evaluation, causing the development period to be prolonged. With the newly developed analysis technology, the bending shape and bending load can be accurately calculated when both ends of the cable are fixed at a predetermined position and angle, thereby streamlining development.

1.8 MB

1.8 MB

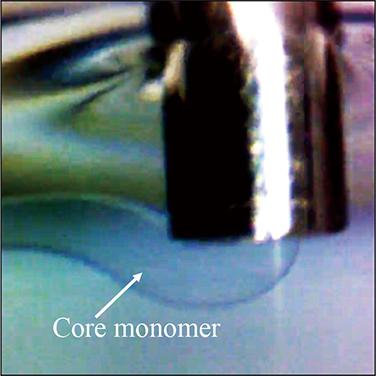

The Mosquito method, a polymer optical waveguide fabrication method invented by Professor Ishigure at Keio University, enables the three-dimensional (3D) formation of core patterns in cladding using a commercially available micro dispenser and a multi-axis syringe-scanning robot. This fabrication method is expected to be used to realize devices required for 3D waveguides such as Fan-in/Fan-out (FIFO) devices, which are essential for the introduction of multicore fibers (MCF). On the other hand, prior studies have mainly examined multimode waveguides, and several issues need to be solved for making single-mode devices. In particular, the core shape tends to deteriorate from circular due to monomer flow caused by needle scanning in the cladding, which is a factor that increases the connection loss with the optical fiber. This paper presents a theoretical and experimental study on the fabrication of single-mode waveguides by the Mosquito method and the formation of circular cores using the method to reduce connection loss with single-mode optical fibers.

2.2 MB

2.2 MB

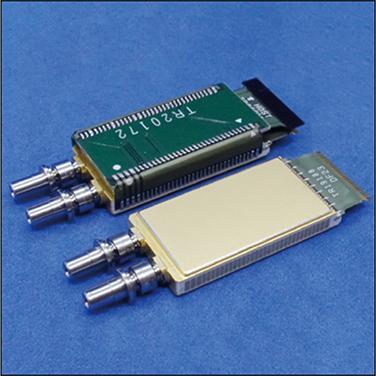

In the construction of 5th generation (5G) mobile communication systems, the transmission speed at the mobile fronthaul (MFH) section is about 2.5 times faster than that of conventional systems. As the signal speed increases, there is a problem of shortening the optical transmission distance due to the effect of wavelength dispersion in single-mode fibers. As a measure to extend the optical transmission distance, we have developed a media converter type optical repeater that converts the wavelength to the 1.3 µm band, where the effect of wavelength dispersion is minimized. The repeater combines waveform generation processing with electric circuits to compensate the transmission characteristics and can be applied to transmission lines up to 30 km. This paper describes the 25 Gbps optical repeater.

1.7 MB

1.7 MB

A digital coherent optical transmission technology has been deployed in not only long-haul and metro networks but also data center networks. Therefore, there is an increasing demand for a coherent module that can be incorporated in small-sized optical transceivers and realize high-speed and high-capacity transmission. Considering the demand, the Optical Internetworking Forum has standardized an integrated coherent transmit-receive optical sub assembly (IC-TROSA) module in August 2019. This paper presents an IC-TROSA type-2 module that integrates a tunable laser for 800 Gbit/s applications.

3 MB

3 MB

Electronic devices using oxide semiconductor In-Ga-Zn-O (IGZO) are attracting attention as next-generation flat panel displays. In order to apply ion implantation technique to IGZO films, Nissin Ion Equipment Co., Ltd. and Nissin Electric Co., Ltd. performed conventional B+ implantation in IGZO films and investigated their optical or electrical properties. The results show that the resistance control of IGZO films by B+ implantation is useful for the IGZO electronic devices, especially for reducing the resistance in the source and drain region of the IGZO thin-film transistors.

2.3 MB

2.3 MB

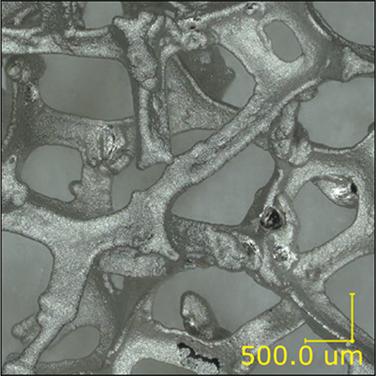

Development of new catalysts is progressing rapidly toward the construction of chemical processes with lower environmental impact. Celmet is a porous metal with a three-dimensional network structure having over 90% of porosity, and therefore is expected to be used as a support material for catalysts with low pressure loss and high deformability. The Celmet support also has the advantage that it can be heated directly by an electrical heating means. This paper revealed that a catalyst coated with CeO2 powder loaded with fine Ru particles on Ni Celmet exhibited practical propane steam reforming performance comparable to commercially available Ru spherical catalysts. Furthermore, NiCr Celmet electrically heated at 500°C was estimated to have long-term durability based on the time-course change in electrical resistance, suggesting that it can contribute to the construction of compact and energy-efficient reactors.

2.6 MB

2.6 MB

Electric wires and conductive spring wires require high strength to withstand repeated bending and maintain high contact pressure. However, the higher the strength of general-purpose copper compound metals, the lower their conductivity. To overcome this challenge, we have developed a new composite wire with a stainless steel coating on a copper core wire by making full use of our wire drawing and heat treatment technologies. This new wire has higher strength and conductivity than beryllium-copper alloys, the strongest of the copper alloys, and is strong against bending and twisting outside stainless steel. This paper presents the results of an evaluation of its resistance to settling and repeated bending, assuming that the wire will be used as a conductive spring or electric wire.

1.3 MB

1.3 MB

Exotic alloys such as Ni-based alloys, cobalt (Co)-based alloys, and titanium (Ti) alloys are widely used for equipment and parts in aerospace and automotive industries due to their superior resistance against heat and corrosion. There has been growing demand for tools for machining these alloys. When cutting exotic alloys, the workpiece material is likely to adhere onto the cutting edge of a tool, resulting in a sudden fracture of the cutting edge of the tool. The tool life is significantly shorter than that of tools for cutting general steel. Thus, demand for cutting tools with stable performance and long tool life has been increasing. The newly developed ACS2500 and ACS3000 are designed to improve wear resistance and fracture resistance by applying a newly developed physical vapor deposition (PVD) coating and special cemented carbide substrate. These coated carbide grades help reduce cutting edge replacement frequency and tool consumption by extending tool life, thus contributing to the reduction of machining costs.

2.1 MB

2.1 MB

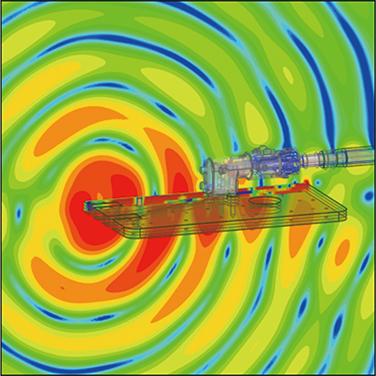

In recent years, computer-aided engineering (CAE) simulation technology has become indispensable in the manufacturing industry as a part of developing products and optimizing process conditions. CAE supports manufacturing processes and product functions based on physical theories. It stimulates the imaginations of designers and production engineers by visualizing invisible phenomena, such as electromagnetic waves, heat, and stress, and connects to the development of new products and improvements of processes. Furthermore, these days more customers request CAE analysis results in addition to experimental results in adopting new products or manufacturing processes. In order to obtain useful and accurate CAE analysis results under these circumstances, it is necessary to develop advanced CAE technology reproducing experimental results, and high-speed calculation servers. In this work, we have realized CAE analysis that could not be handled previously, by increasing the calculation efficiency and functional performance of the calculation servers. This article gives an introduction to the details of these calculations in various analytical fields.

2.4 MB

2.4 MB

There is a rapidly expanding market for industrial solutions to improve productivity and safety by transmitting all kinds of information in factories and cities to the cloud at high speed and with low latency through 5th generation mobile communication systems and analyzing the information using AI. We have developed an industrial 5G terminal that can be used in both public 5G networks, which are deployed by mobile carriers, and local 5G networks, which are built by companies and local governments within a limited area. This 5G terminal has an edge computing function and ease of installation of applications that meet user requirements. The combination of edge computing in this 5G terminal and cloud computing in a cloud server makes it possible to realize optimal solutions that meet user requirements.

273 KB

Sumiden Communication Engineering Co., Ltd. has been involved in the nursing care service industry through the provision of the nursing care service billing system “Care Time,” which calculates service charges based on helpers’ service records and bills payers, for about 20 years. We have recently developed a WEB system that can share data with the nursing care service billing system and started offering it to nursing care service companies as a subscription service.

291 KB

As fluorescent lamps installed in cable tunnels (tunnels for laying communication cables) are being replaced with LED lights, we have been selling immersion-proof LED light fixtures with an IP67 (dustproof and immersion-proof) rating since 2013. However, their use in narrow spaces has been limited due to their external dimensions. This time, we have released compact and easy-to-install LED light fixtures that can be installed in narrow spaces while maintaining the advantages of our conventional products.

0.6 MB

Currently, most power cables are XLPE cables, which use crosslinked polyethylene (XLPE) for insulation. XLPE has excellent heat resistance due to its crosslinks, but it shows no fluidity with heat and its material recovery is difficult. In addition, the longer the cable to be produced, the longer the lead time may be, because manufacturing XLPE cables requires a crosslinking reaction process to form a network structure and a drying process to exhaust by-product gases from the reaction. Against this backdrop, we have developed environmentally friendly non-crosslinked insulated power cables that can contribute to improving productivity.

1.7 MB

The market for industrial robots is rapidly expanding due to labor shortages, cost reductions, and productivity improvements in industry, and the demand for precision bearings (linear guides and ball screws) is growing. Profile grinding is often used to grind the rolling surfaces of the main parts of bearings because it requires particularly high productivity. Profile precision depends on the diamond rotary dresser (RD) that trues and dresses the profile grinding wheels. To further enhance efficiency, conventional and general grinding wheels have been replaced by rigid wheels, which use the most rigid material after diamond and enable high-speed grinding. In step with this, the development of profile RDs with high abrasion resistance has been required. In response to requests from the bearing industry, we have developed and begun marketing a new RD for rigid wheels, such as vitrified cubic boron nitride (CBN) wheels, using our original plating technique.

1.1 MB

A milling cutter is a cutting tool with a cutting edge on the periphery, end face, or side face. Various kinds of parts are machined by revolving the cutter. Milling cutters with indexable inserts are widely used today for various types of machining. Recent performance improvement of machine tools is increasing the need for tools specialized in high-efficient machining in the automotive, aerospace, ship building, industrial machinery, die-mold, and other sectors to improve productivity. Environmentally friendly machining has also become a focus of attention as a part of CO2 emissions reduction activities to achieve a decarbonized society. Sumitomo Electric Industries, Ltd. has recently developed the SEC-Sumi Dual Mill DMSW series (DMSW), which enables more efficient machining and contributes to increasing productivity and saving energy.

1.3 MB

Copyright of the paper contained in SUMITOMO ELECTRIC TECHNICAL REVIEW belongs to Sumitomo Electric Industries, Ltd.

The paper is to be used solely for private, reference purpose, and reproduction without the permission of the copyright holder is prohibited.

Meet the Authors of the SUMITOMO ELECTRIC TECHNICAL REVIEW

We at Sumitomo Electric Group are driven to pursue technological innovations to create value for a better world.

Learn more