Others (Fundamental Technology)

Security

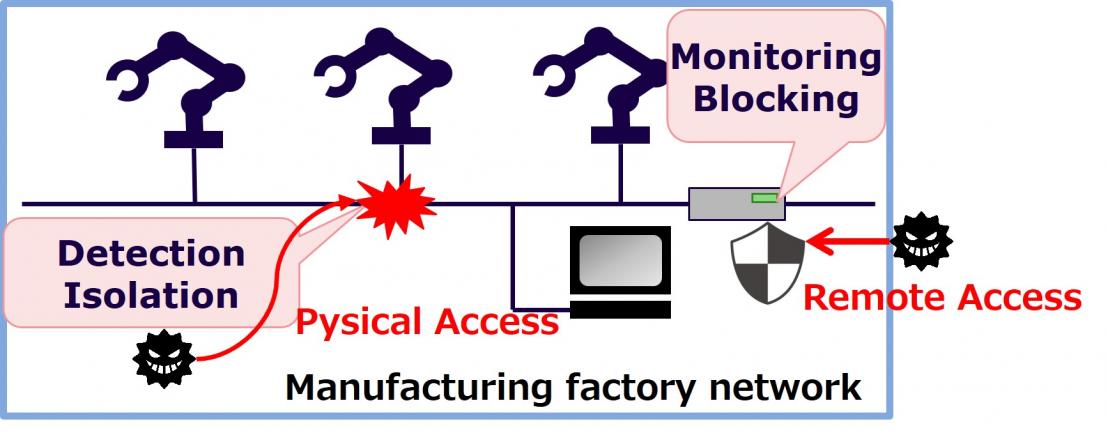

Cybersecurity for Manufacturing Factories

From the current cyberattack situation, to ensure cybersecurity for our manufacturing factories, we develop cybersecurity Identification, Protection, Detection and Response technologies. In detail, we develop risk analysis and assessment methodologies for future factories which become more complex by using advanced technologies, and new countermeasure technologies (intrusion detection/prevention, root cause analysis and so on) against new cyberattacks targeting advanced factories.

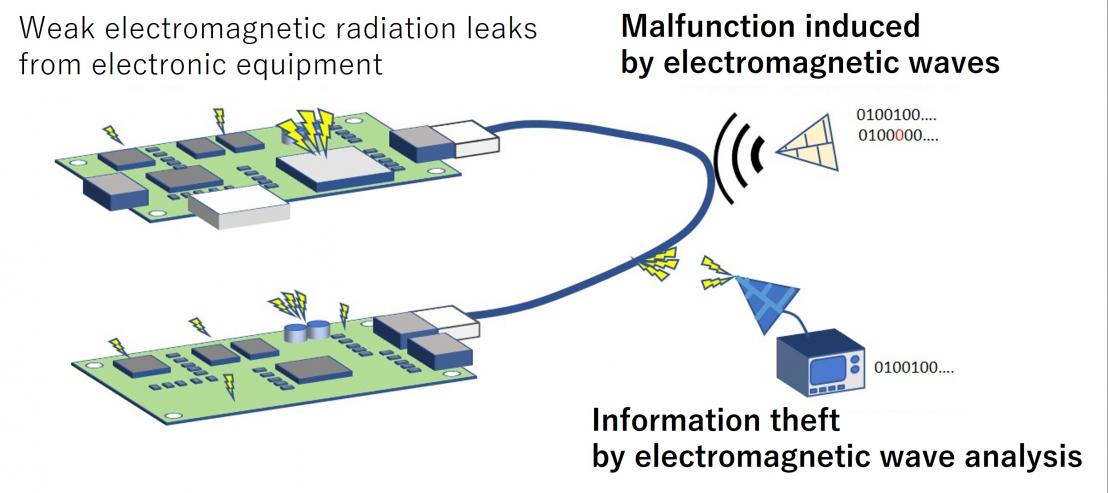

Cyberattack Research from Hardware Perspective

With the growing concern over cyberattacks that exploit physical phenomena—such as side-channel attacks that theft information by analyzing extremely small level electromagnetic emissions—we study which physical phenomena could potentially be used for such attacks and assess the severity of the threats. Based on these assessments, we evaluate the vulnerabilities of our products and develop corresponding countermeasures.

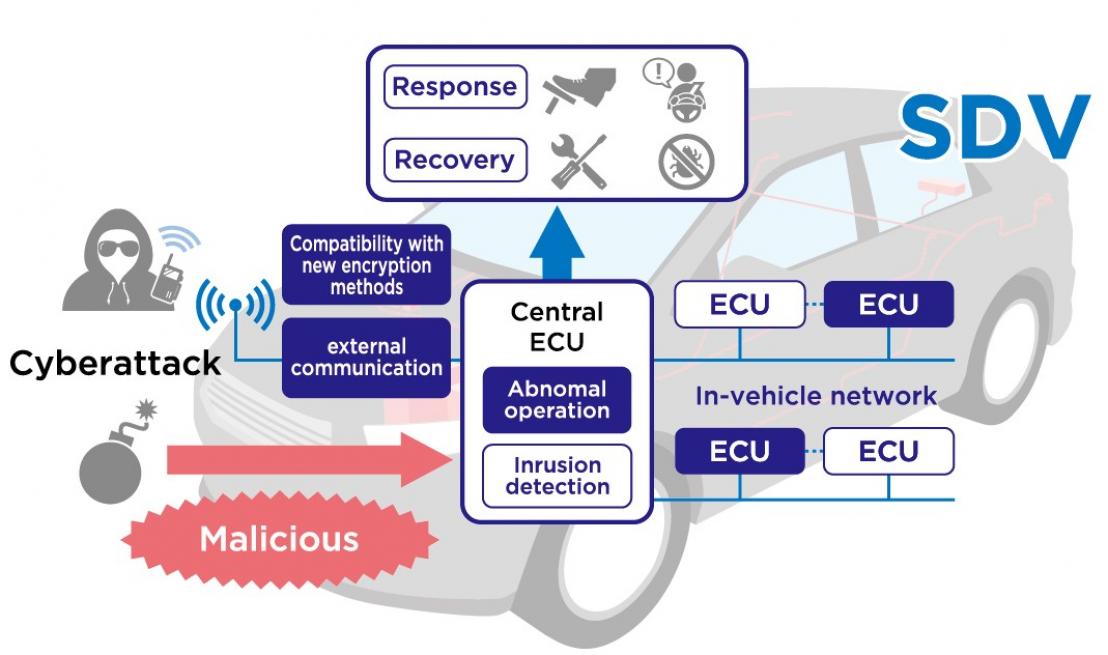

Automotive Security

With the advancement of autonomous driving vehicles and connected technologies, we have proactively developed cybersecurity measures for state-of-the-art vehicles. We have enhanced cybersecurity R&D with AI and machine learning-based approaches and analysis capabilities that utilizes detection for unknown cybersecurity attacks, next-generation cryptographic technologies, and evaluation of in-vehicle communication.

Factory Support

Realizing the Next-Generation Smart Factories

We are enhancing productivity and value creation by deepening the digital transformation (DX) of our core manufacturing strengths through advanced DX and AI technologies. By leveraging cutting-edge xR technologies (AR/MR/VR/SR), we are working toward the realization of next-generation smart factories, while also driving innovation to create new products and businesses. Through these initiatives, we aim to help address societal challenges and contribute to the achievement of the SDGs by building a society where everyone can enjoy a high quality of life.

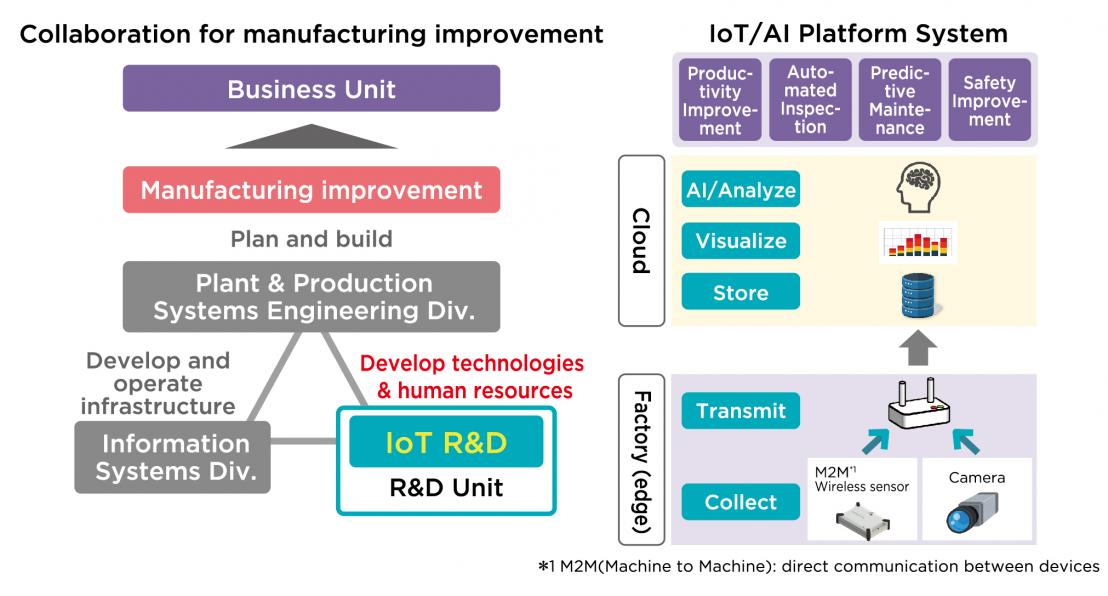

Strengthening Manufacturing through DX

We are accelerating digital transformation across our production sites by leveraging IoT and AI technologies—including sensing, wireless communication, data analytics, and machine learning—to tackle core challenges such as improving productivity, automating inspection, enabling predictive maintenance, and enhancing safety. In parallel, we are also developing robust system platforms and cultivating talent to support and sustain these advancements.

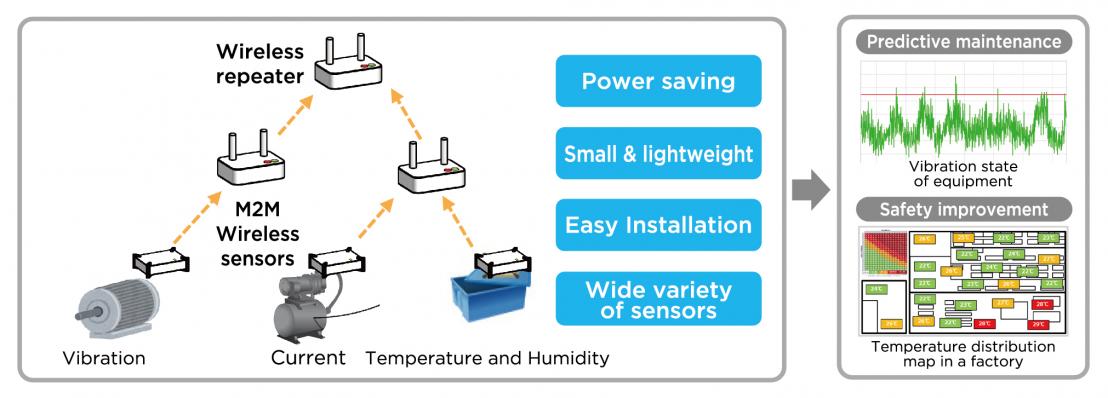

M2M Wireless Sensors

Our wireless, battery-powered M2M sensors enable easy collection of facility data without the need for complex wiring. The collected data can be visualized and leveraged to drive a wide range of operational improvements.

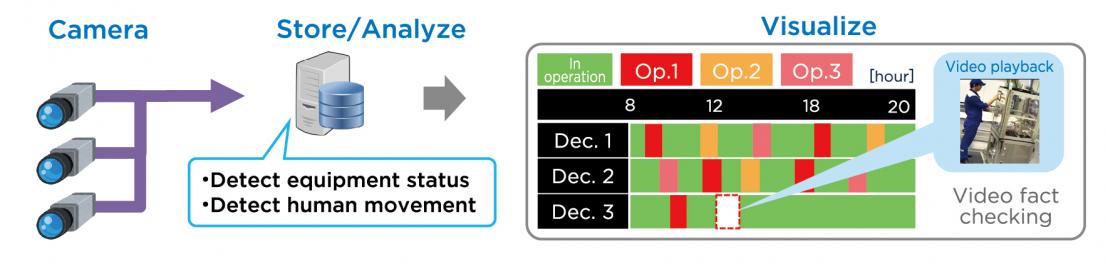

Video Analysis Tools

Older equipment often requires physical modifications for data collection, and gathering information on human activity, such as operator movement, is especially challenging. Our AI-powered video analysis tools address these issues by extracting operational data—such as uptime, downtime causes, and setup durations—from camera footage. This enables automated time tracking, identification of time overruns or inconsistencies, and video-based reviews for root cause analysis.

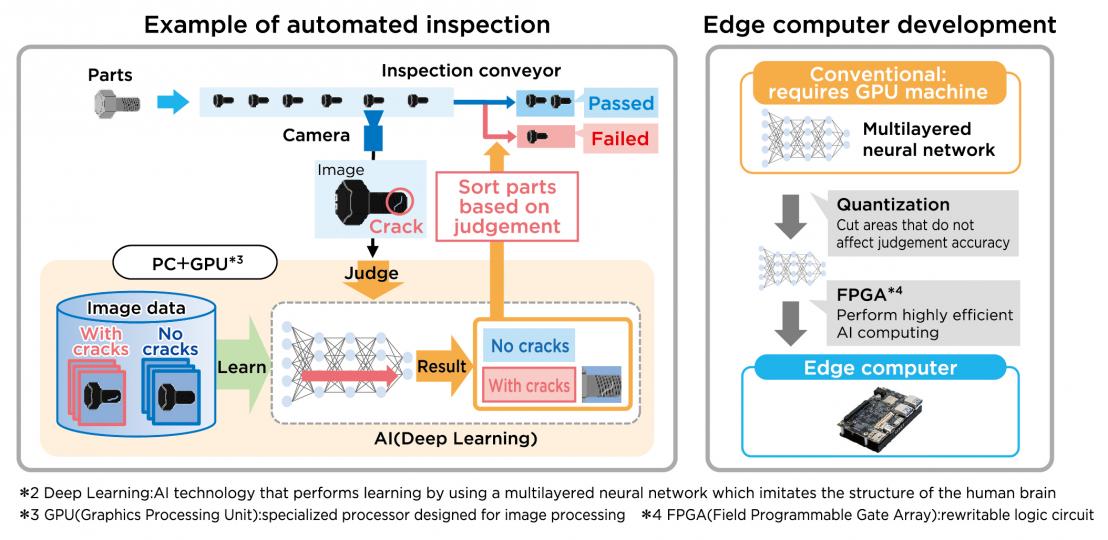

AI-Based Automatic Inspection

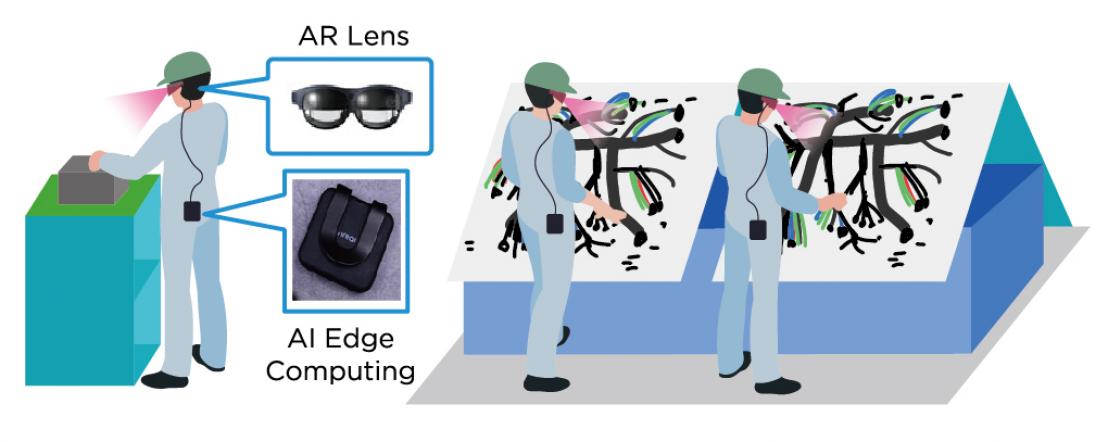

In many inspection processes, securing and training personnel for visual inspections has become a problem. We are promoting on inspection automation utilizing AI technology (Deep Learning). In parallel, we are developing edge computer aimed at reducing costs and miniaturizing automatic inspection systems.

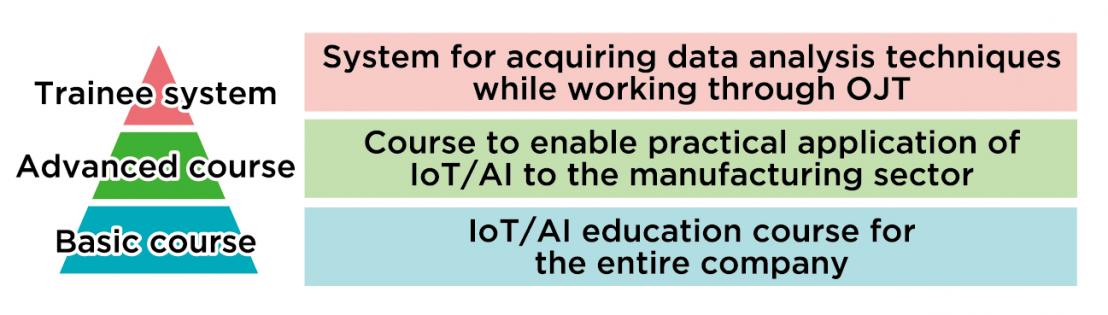

IoT/AI Talent Development

We have prepared a three-stage training program to enable each business unit in our group to proactively utilize IoT and AI technologies, thereby promoting the development of IoT/AI talent across the company.

Frontier Technologies

Carbon Nanotubes (CNT)

Carbon Nanotubes (CNTs), in their single-crystal form, offer tensile strength more than 20 times greater than that of steel, making them highly promising for use in structural components for automobiles, aircraft, and buildings. They are also considered the only known material with the potential to meet the extreme strength requirements of space elevator cables. By developing sustainable, high-performance materials, we are helping to advance SDG 12: Responsible Consumption and Production and contributing to a more resource-efficient future.