Analysis Technology

Analysis and Evaluation

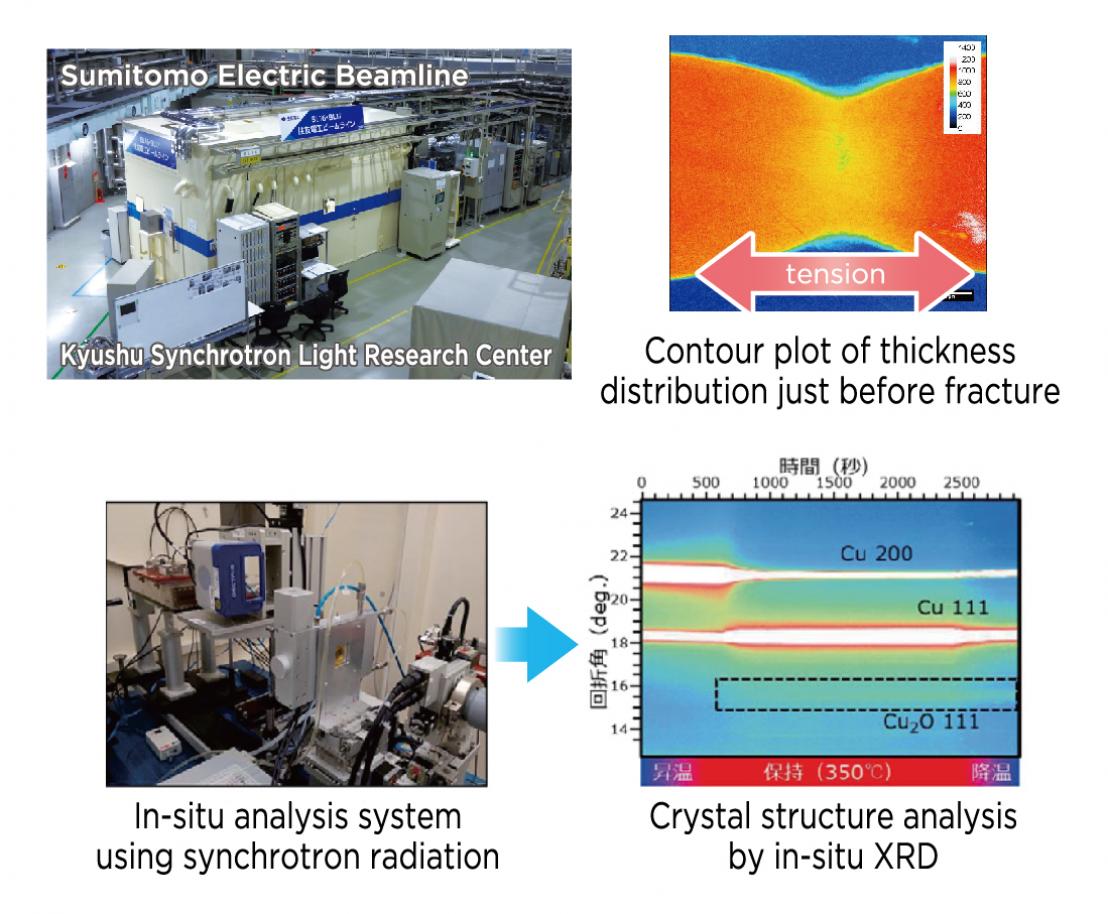

In-Situ Analysis Using Synchrotron Radiation

We are advancing technologies for material structural analysis and real-time reaction observation using cutting-edge large-scale research facilities. Our proprietary Sumitomo Electric beamline is actively employed for synchrotron radiation analysis.

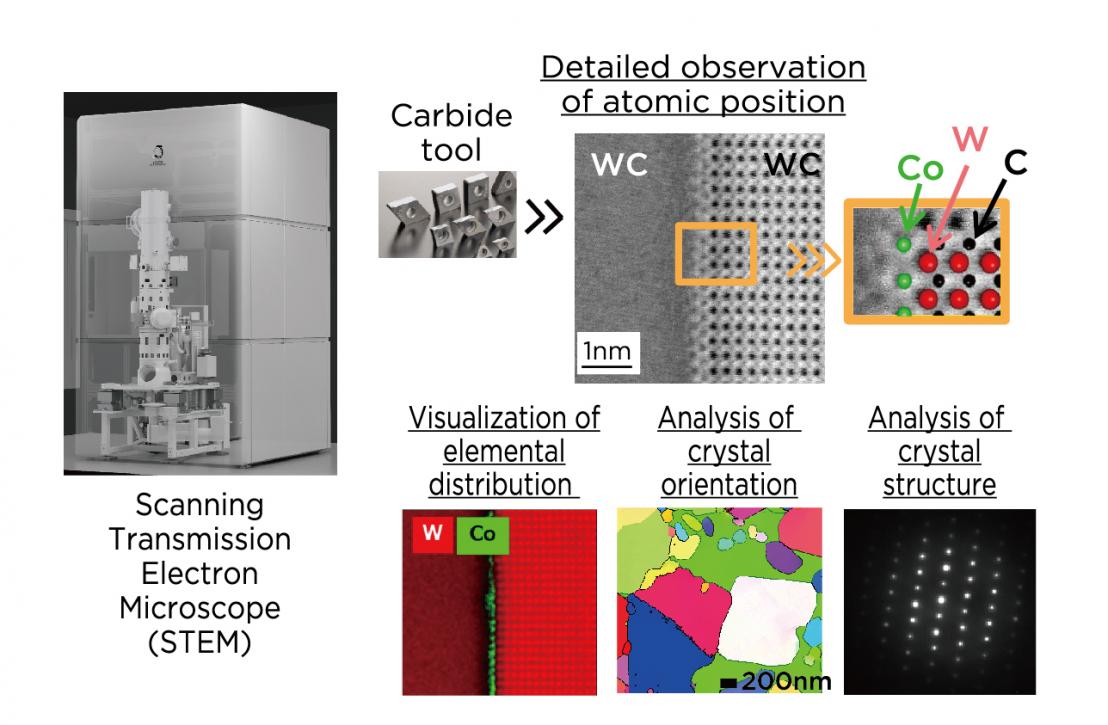

Atomic-Level Structural Analysis

Using ultra-high-resolution scanning transmission electron microscopy (STEM), we conduct not only atomic-level microstructural observation and crystal structure analysis, but also advanced techniques such as crystallographic orientation analysis. These capabilities support the development of high-quality, high-performance materials and devices.

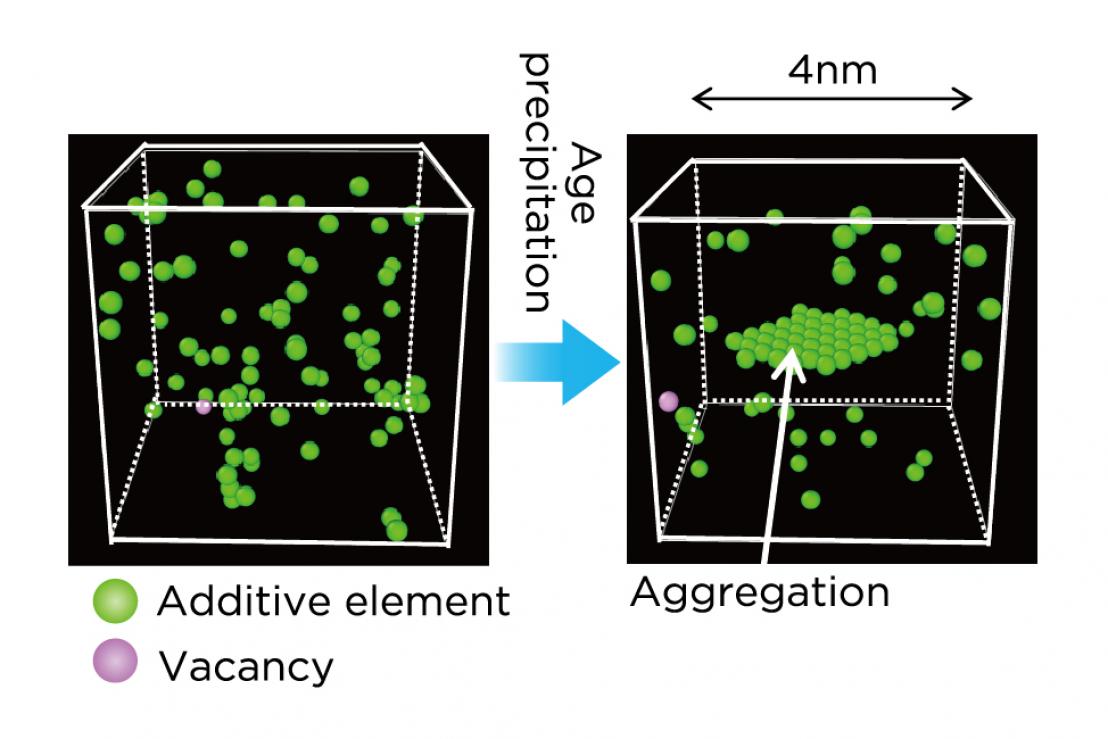

Computational Design of Aluminum Wiring Harness Materials

Aluminum wire increases in strength over time as certain alloying elements cluster at the atomic level. To support the selection of suitable elements and optimize aging conditions, we are developing simulation technologies that visualize the atomic clustering process.

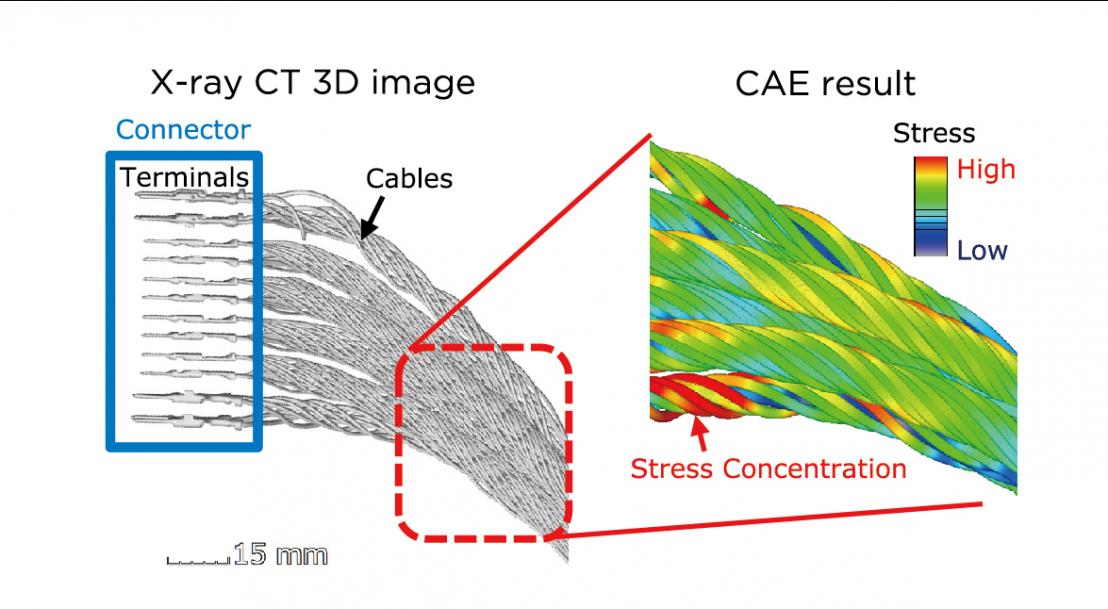

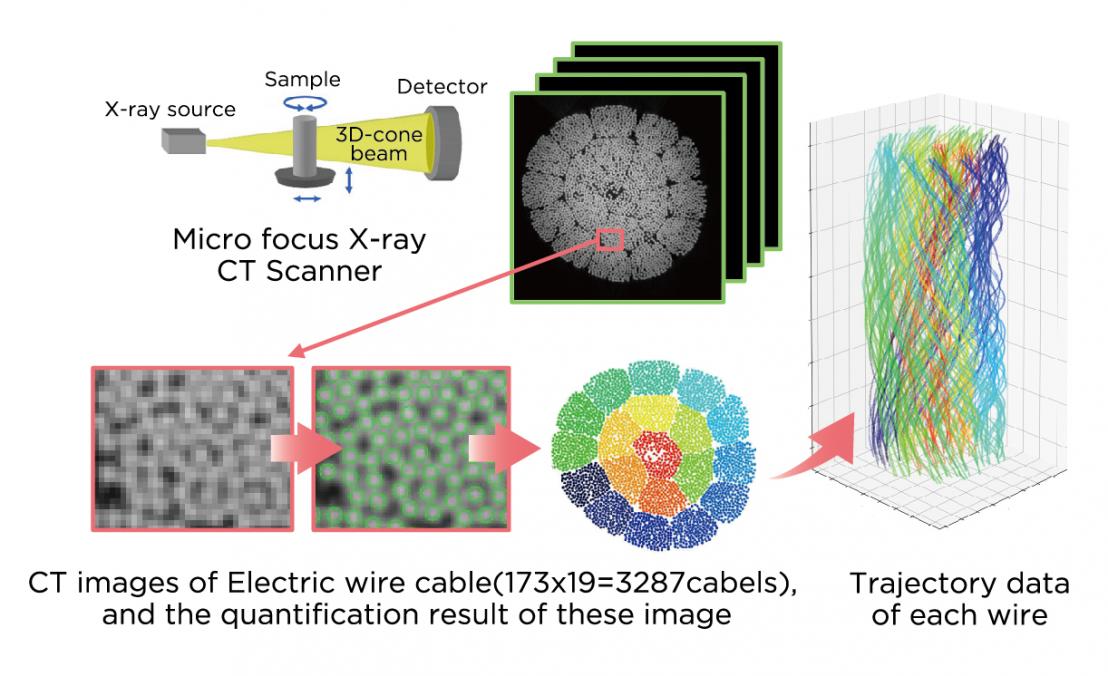

High-Accuracy Simulation and Lifetime Prediction of Wires

We are developing simulation-based technologies to accurately predict the lifespan of electric wires used in automotive wiring harnesses and robotic moving parts. By utilizing X-ray CT and AI to automatically track wire motion and trajectories, this data is incorporated into simulation models to enable high-precision life prediction.

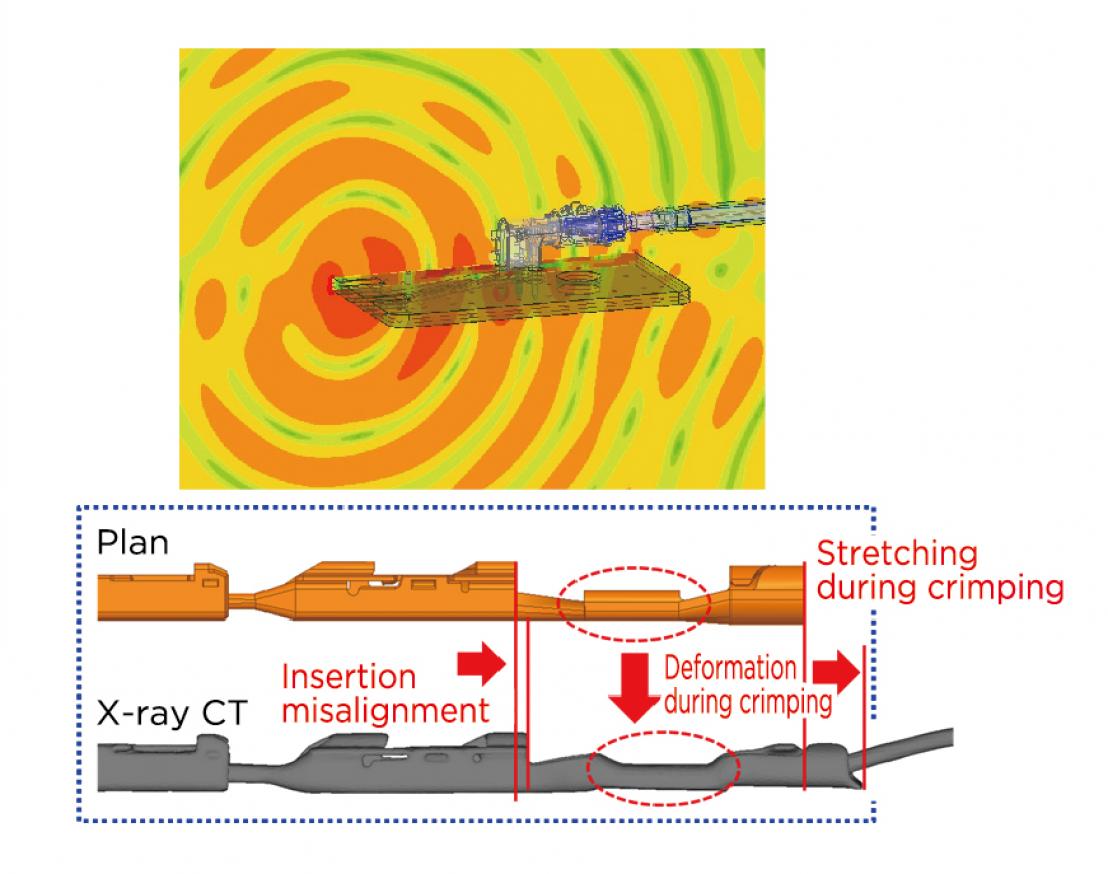

Electromagnetic Field Analysis

In developing products that support high-speed communication technologies such as CASE and 5G, we apply high-frequency electromagnetic field analysis to product design. To accurately capture the behavior of short-wavelength electromagnetic waves, we fully leverage large-scale computing servers and integrate real-world observation techniques that account for microstructural changes occurring during manufacturing.

Quantification of 3D Structural Analysis Using Advanced Data Techniques

We visualize the three-dimensional structure of products and apply advanced data analysis techniques to quantify structural characteristics. This contributes to improved quality and promotes digital transformation (DX) in product design.

R&D Digital Transformation (DX)

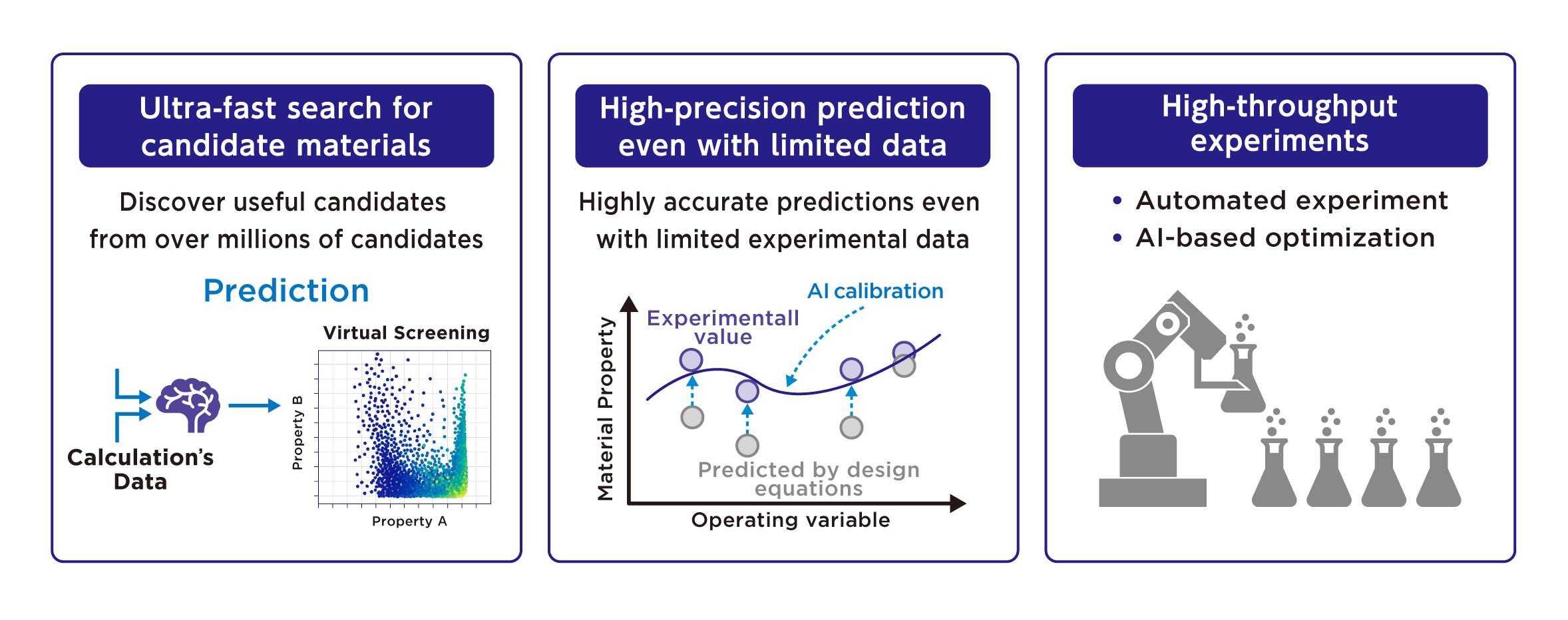

Recent advances in materials development have intensified competition in digital R&D, driven by high-performance computing (HPC). We are advancing research in materials informatics (MI) to accelerate material discovery and process informatics (PI) to optimize manufacturing processes. These initiatives aim to transform conventional trial-and-error cycles into simulation- and data-driven approaches.

MI/PI

By training AI on the physical principles of materials, we enable it to explore candidate materials up to 100,000 times faster than human researchers—opening the door to discoveries beyond human intuition. In parallel, we are building databases to systematically accumulate experimental data and developing techniques capable of making highly accurate predictions even from limited data sets.