Laser Optics

Laser Optics

Laser processing realizes a non-contact and highly precise processing method to cut materials at high speed using a lens to focus energy millions of times greater than the light found in the natural world. Laser processing machines that realized this technology play an active part in a wide variety of industries because of its high processing performance and overwhelming cost performance. The mission of laser optics manufacturers is to realize the maximum potential of the laser processing machine.

Lineup

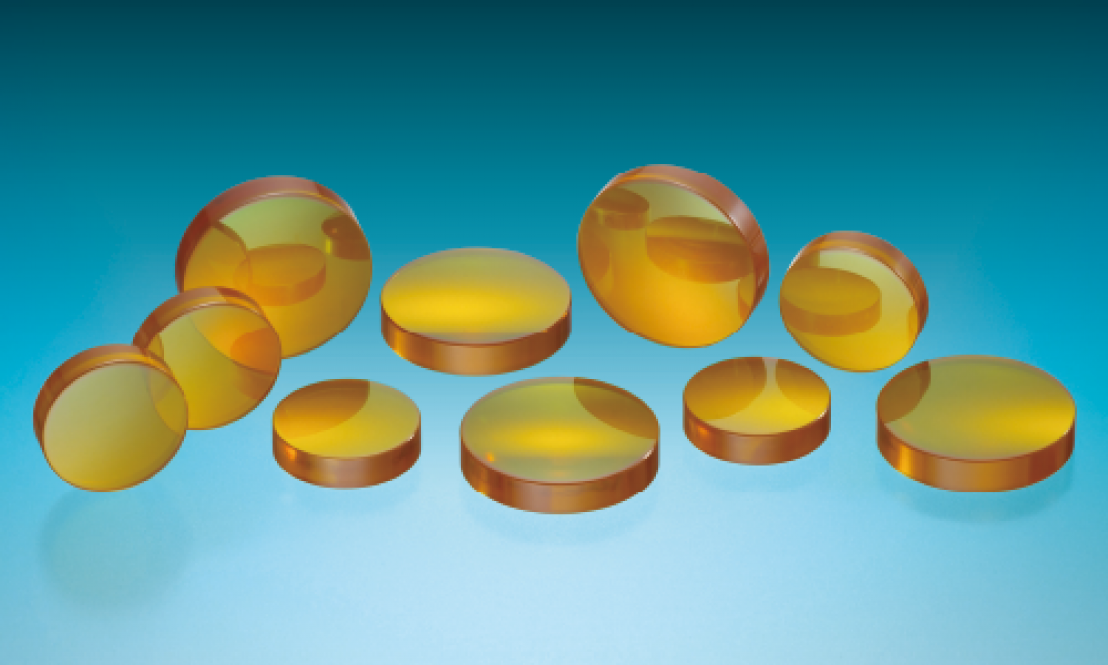

Lens

Lenses which minimize absorption of the laser beam, which has significant influence on processing quality, and realize high focusing performance and economy. We provide various lenses such as normal plano-convex lenses, meniscus lenses, aspherical lenses which realize high concentration, and pressure-resistant lenses used for laser processing machines.

The adoption of an aspherical surface shape minimizes spherical and realizes a small spot size.

Aspheric lens

Aspheric surfaces can effectively reduce spherical aberration and realize a diffraction-limited performance. Optimal solutions for high precision and high quality laser materials processing by short focal length and large input beam diameter. A spherical lens with spherical aberration shows differences in focal positions of light rays depending on their distances from the optical axis. Our aspheric lens realize smaller spot diameter than a conventional triplet lens by spherical lenses.

Mirror

Mirrors which have both the durability and the reliability of transmission of a high power laser beam without decreasing its quality. We have various lineups that zero phase shift mirrors, 1/4 phase retarders, metal mirrors, and parabolic mirrors for focusing high power laser light more than 5kW, and scan mirrors for galvanoscanners in which oval and polygon shape silicon mirrors operates at a high speed.

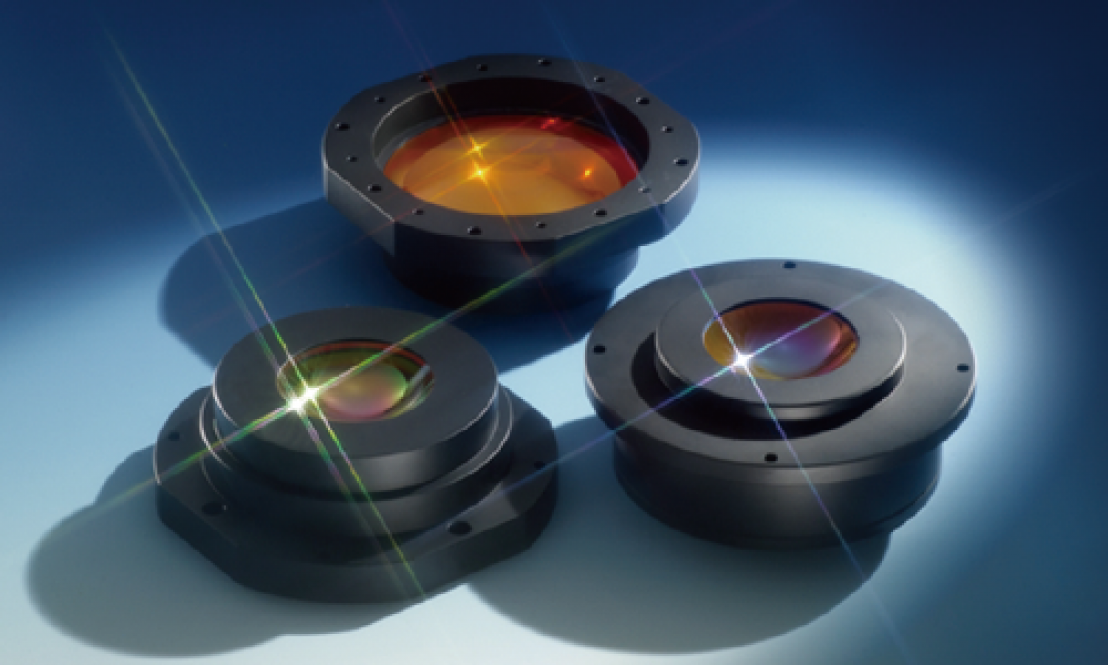

F-Theta Lens

This lens focused a laser beam scanned with a scanner, etc. It is used for high speed micro drilling of printed circuit boards, high speed marking of electronic parts and resin parts, etc. This lens minimize distortion and make a laser beam incident almost perpendicularly to the work piece. It is suitable for processing such as laser micro drilling. This lens is suitable for markers, plotters, etc. of which you want to scan a wide area quickly.

F-Theta Lens

This lens focuses a laser beam scanned with a scanner, etc. It is used for high speed micro drilling of printed circuit boards, high-speed marking of electronic parts and resin parts, etc. Highly precise telecentric lenses minimize distortion and make a laser beam incident almost perpendicularly to the work piece. It is suitable for processing such as laser micro drilling. Wide area non-telecentric lenses is suitable for markers, plotters, etc. of which you want to scan a wide area quickly.

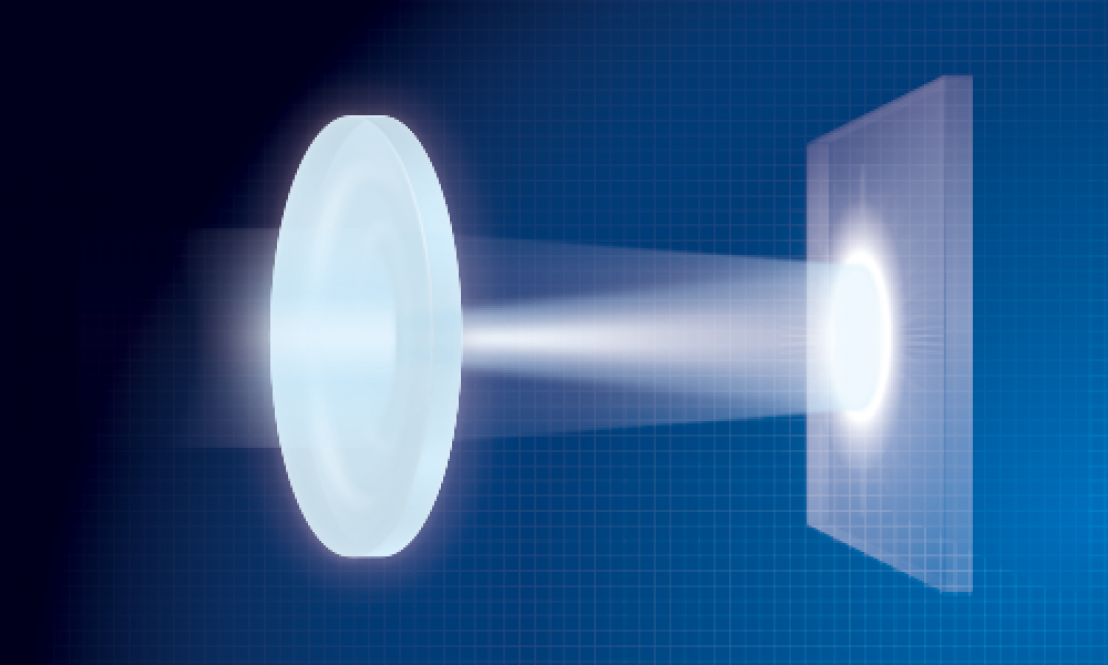

Beam Shaper

A beam shaper is an element that a single-mode beam is converted into a flattop beam, a ring-mode beam or a ring + center mode beam. This is effective in cutting, welding, drilling, patterning. They are ready that a single element type included condenser lens function and a non-focus unit. It is selectable an aspheric type and DOE (Diffractive Optical Elements) type on demand of beam shape. It is acceptable to shape not only circular but a square or a line by DOE type.

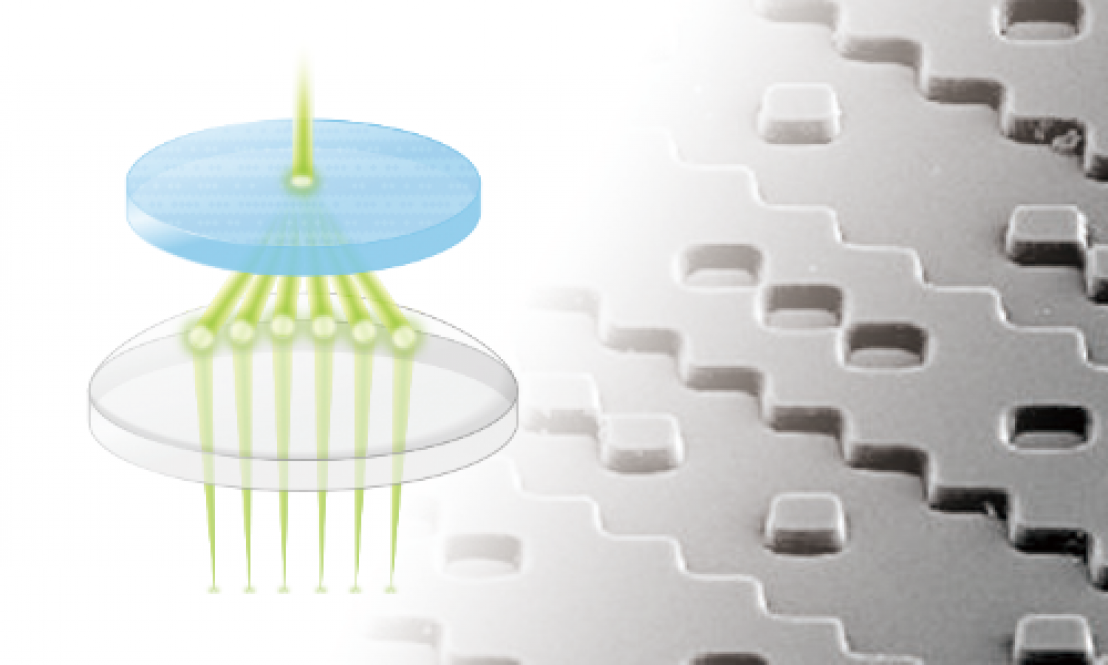

Beam Splitter

The diffractive beam splitter is a DOE, Diffractive Optical Elements, that splits laser light into multiple beams and realizes simultaneous focusing on multiple points by combining lenses. Various beam intensity patterns are formed by line or matrix distribution.

Inquiry about Laser Optics

Feel free to contact us for laser optics as well as questions, feedbacks, and requests.

An expert staff relevant to the inquiry will respond you with an appropriate answer.